Control Upgrades

Package Pros offers controls system upgrades and replacements. The control system has a proven track record with dozens with this design in operation in many production facilities.

Overview

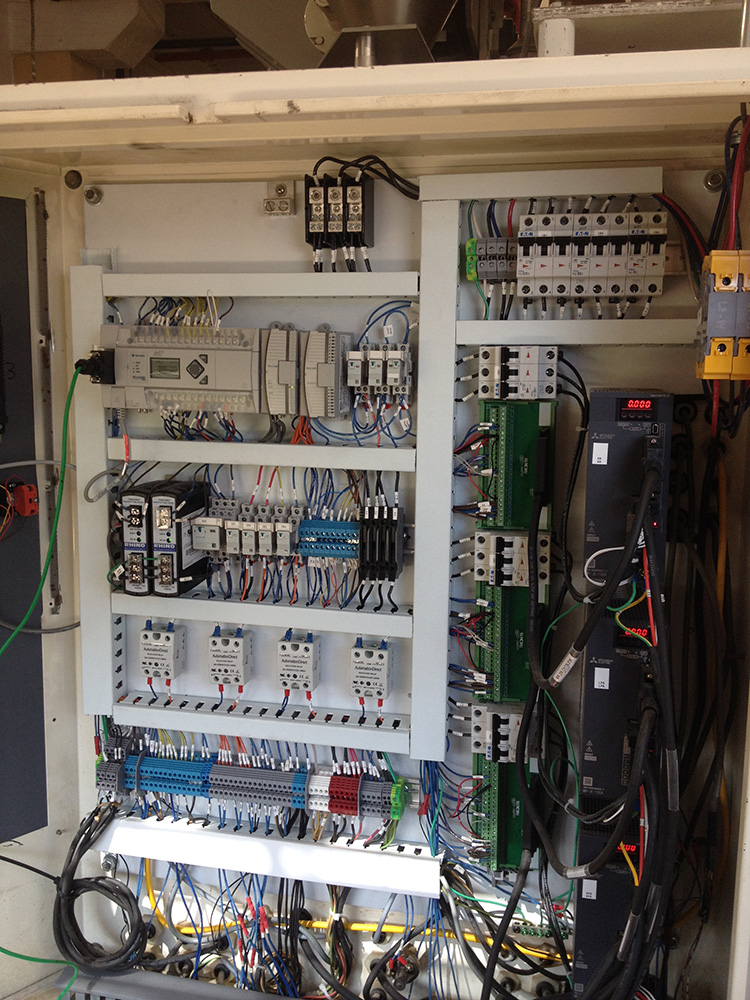

The Package Pros control rebuilds consist of several key components. First, a new back panel is installed, complete with all-new electrical elements, seamlessly fitted within the existing enclosure. Second, an updated operator station, known as the Human Machine Interface, is introduced to replace the previous one. Finally, a servo fixture is incorporated into the machine’s center, connecting to the film pulling belt shafts and control panel, and easily coupling with the rollers and belts.

Typically, bagger rebuilds are completed within approximately three days at our facility. This overhaul provides customers with numerous advantages, including increased operational speeds, reduced setup and scrap, minimized downtime, and lower maintenance requirements.

Here’s what our Controls Upgrade Services can do for you:

Controls

The Hayssen control package boasts an Allen-Bradley or Omron PLC and incorporates a temperature module for seamless temperature control linked to both the PLC and a touchscreen. The 7-inch Allen-Bradley or Omron color touchscreen offers a multitude of operator functions, status monitoring, messaging capabilities, and recipe management.

The servo system is compatible with Mitsubishi, Omron, or Allen Bradley servos and drives, featuring built-in registration control for precise film stopping and positioning. Additionally, there are other control components, all neatly integrated into a customized back panel designed to snugly fit your existing enclosure. These components are non-proprietary and can be readily sourced by maintenance personnel through parts suppliers.

Package Pros specializes in managing filler and downstream integration, providing comprehensive training and support during the production startup phase. They can tailor installations to your exact specifications and furnish you with schematics and bill of material lists.

Package Pros also extends ongoing control support and offers the option of an accessible Wi-Fi router for remote access, allowing their engineers to diagnose issues and implement custom updates as needed. Moreover, productivity data can be effortlessly shared through push reports to further enhance your operational performance.

Operator Screens

There are more than a dozen helpful operator screens with a similar scheme to Hayssen, Machine adjustments can be made while the machine is running. The main screen provides film jog, tracking, single/continuous bags, and empty and full bags. Once set up (or a recipe loaded), the main screen is all that is needed. Other screens set the machine speed and bag counters. Two screens show machine timing and can be adjusted using a 0-360 on/off selection for all actuators. Another screen allows temperature adjustment for sealing with alarms. The Bag screen provides bag length, film registration, placement, and film setup. A recipe screen provides a means to save and load all machine setup variables for rapid changeover. There are screens to jog the motors and to actuate the pneumatic valves. There are screens for filler/doser setup. There is a screen for adjustments of film tension. There is an optional screen for maintenance information.

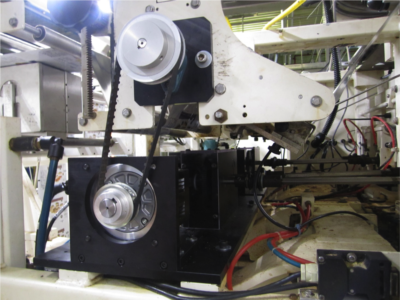

Servo Fixture

The servo fixture is built to easily mount and couple to the existing registration roller and pull belts. The fixture is machined with high grade ½” aluminum and all is anodized. There are (2) 1Kw servo motors. One servo motor is coupled to the registration roller with a timing belt. The other servo motor uses a timing belt to run a pair of spur gears that are then coupled to the 2 pull belts shafts. In this way, the mechanical drive provides twice the torque advantage over a direct drive system. These 1KW motors provide plenty of power. In one extreme case of an accident, a customer lost the registration motor and was able to run the machine successfully with just the pull belts. Other applications have had these servo motors running 76 bags/minute for 20 hours a day. These motors are sized to be strong and cool running.

Our Control System Upgrades

Benefits

- Creates Smooth Motion

- Allows Faster Machine Speeds

- Reduces Wear and Maintenance

- Standard “off the shelf” Control Parts

- Easier Operator Controls Color Touch Screen Guides

- Very High Registration Accuracy

- Easier service because of standard parts (AB)

- Film Tracking Improves—film is pulled smooth and even

- Customized programming, schematics and parts lists provide

Features

- Allen-Bradley, Micro 850 or Omron PLC

- Integrated Temperature Control

- 7″ Color HMI or AutoDir Touch Screen, 10” Option

- Over a dozen touch screen pages

- Modular/Replaceable Controls

- Optional Stainless Enclosure

- 2 Mitsubishi Servo Drives, Allen Bradly or Omron – Registration high accuracy stopping.

- High Performance Motors (Capable of 120 cycles/minute)

- “On the Fly” adjustments of Speed and bag Length.

- Belt and gear drive assemblies

Let's Get Started

No matter your VFFS machine, the controls can be upgraded and made modern giving your machine superior operation and functionality. It will look and run like a modern bagger and perform as well as any competitive bagger in its class. With higher speeds, reduced scrap and maintenance, customers often pay for the control upgrade in a very short time, sometimes just months. Let Package Pros evaluate your needs and provide a great solution. We stand behind and support this control system, as we do all our products.

What comes with a typical Hayssen controls upgrade?

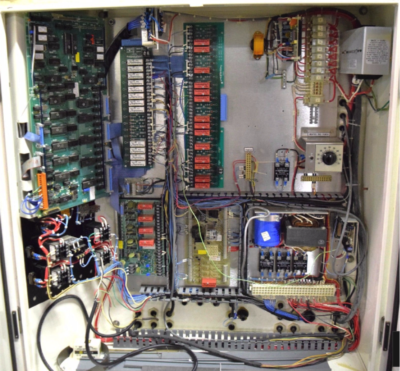

Before – Older Hayssen dedicated Proprietary push button controls.

After – Upgraded Control Touch Screen with Start, Stop, Power and E-Stop

We remove the entire old operator control panel and replace with an Allen-Bradley touch screen. The old integrated circuit chip control was fixed and inflexible. The touch screen can be programed and customized as per your specific needs.

Before – The older transmission box and DC motor are removed.

After – The FFI Upgraded Hayssen (2) Servo Motor replacement. One Servo drives a spur gear to drive both belt shafts. Includes torque increasing reduction ratio and easily serviceable timing drive belt. Second Servo drives film registration roller. (Clutch break removed)

Before – The old Hayssen main control panels removed. Input/Output wiring is disconnected

After – The brand-new Allen Bradley PLC based control panel with Servo drives is installed.

Package Pros

Package Pros offers various upgrades to your existing VFFS baggers. We can tailor the upgrade of your bagger. We offer mechanical upgrades, and controls system replacement. The control system has a proven track record of 10 years of deployment with this design in operations in many production facilities.

Contact Us

Call us

(281) 993-6163